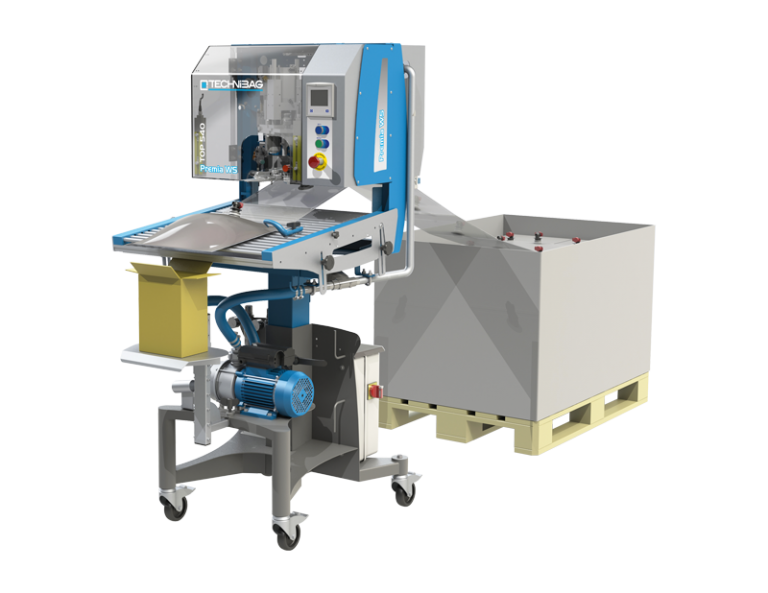

The semi-automatic PREMIA WS filling machine is designed to meet filling needs for vacuum bags from 2 L to 20 L (in “Web” and “Single” mode), Pouches from 1.5 L to 5 L (in “Single” mode) and Cheertainer® recipients (in “Web” and “Single” mode). It can be used for all types of liquids and semi-liquids for both food and non-food products.

Specificities

- Automatic operation without manual feeding of the bag in Web mode.

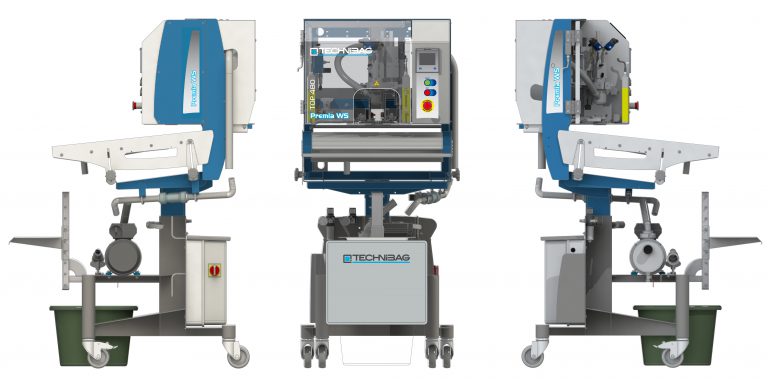

- Start of cycle (DAS safe and automatic start-up), removal of tap, creating a vacuum in the pouch, metering and filling, nitrogen injection and/or sweeping, reinsertion of tap, ejection of full pouch.

- Cutting assistance in Web mode and automatic presentation of the next pouch.

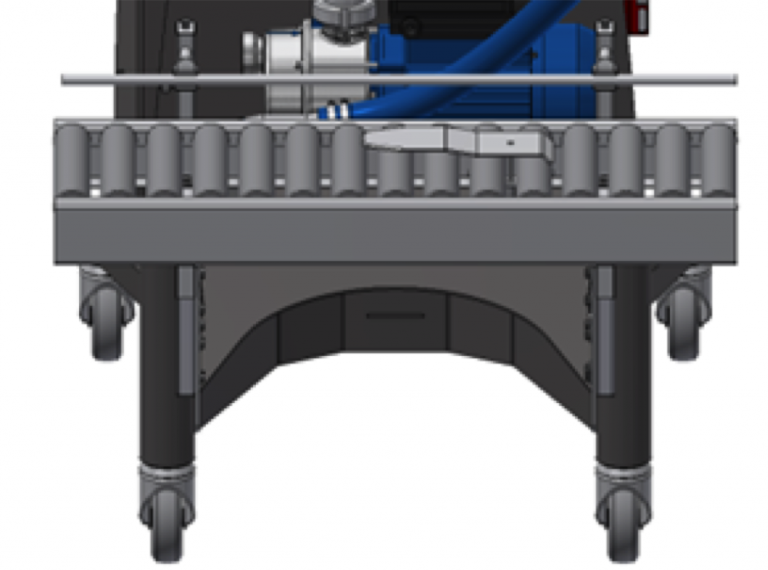

- Box holding helper placed on the free rollers : facilitate the introduction of the bag by keeping the box in good position on the conveyor. The operator have free hand after the box is formed.

- Greater efficiency and comfort, from the start of the filling cycle to crating.

Integrated box support conveyor

- Integral with the filler

- In stainless steel

- Can be positioned either at left or right of the boxing station, depending on line direction

- Have a depth adjustable stop and can accept box from 3 to 20 L.

Web / Single modes

- « Web » mode : automatic machine feed with bags attached to each other in strips. This bag technology is recommended for medium and large production runs carried out with semi-automatic and automatic filling machines. It allows better ergonomics and productivity gains by (partial or total) automation of handling operations (loading, cutting etc.).

- « Single » mode : manual machine feed with individual bags. Single mode is suitable for small and medium production runs carried out with semi-manual or semi-automatic filling machines.