Performance, modernity, reliability

Result of an ambitious R&D program developed by TECHNIBAG, B’BOOSTER TOP 900 was designed to be the most efficient and reliable automatic flexible bag filling machine on the market. It meets the needs for intensive filling of bib or pouch (option) with fully mastered quality and optimal user comfort. It can be integrated into single, double or triple head lines.

Very high speed

- High filling rate of 15 bags per minute (for 3L bags).

Brushless motor: electric axes for fast and precise movements

- Innovative and robust technology: positioning of the filling head and intake / removal of the valve by electric jacks.

- This technological choice guarantees controlled filling quality, reduced maintenance costs and air consumption, and optimal filling rates.

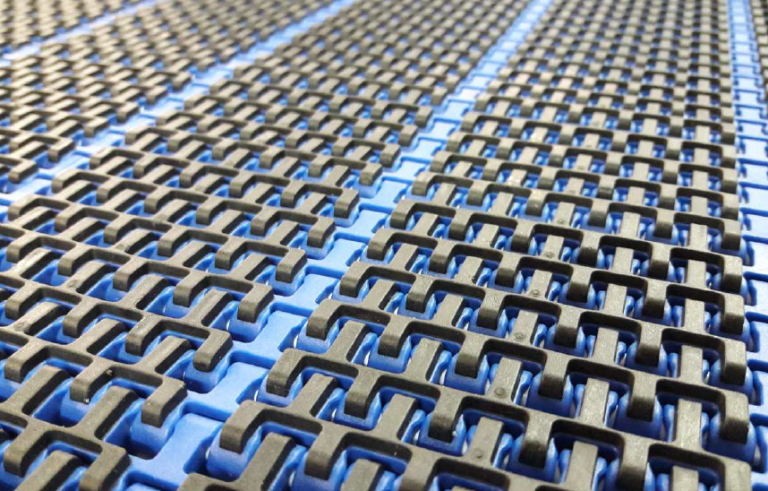

Pocket transfer mat and automatic adaptive cut

- Format changes in less than 5 minutes

- Adjustable packing speed, controlled fall of the full pocket into the box

- High transfer rate, guaranteed for liquids conditioned up to 85 ° C

- Food industry cleanability

Clean high performance filling head

- Separate, fully cleanable vacuum and nitrogen injection circuits

- Ultra-hygienic design according to EHEDG and 3A standards

Connected machine: industry 4.0

- Remote maintenance: remote control, help with fault diagnosis

- Data transfer:

- production management (management of recipes, display of rate and throughput information, management of the production schedule with progress status),

- statistics (display of statistics – machine usage time by mode, list of recipes with number of BIBs produced, total number of BIBs, priming, cleaning, etc.)

- the management of the machine park (display of the time remaining before preventive maintenance).

- as an option, possibility of accessing the HMI functions directly from your smartphone, tablet or PC.

Let’s study your project! !

Whatever the specificities of your applications and processes, TECHNIBAG commits its expertise to your side and provides the appropriate solutions and services to guarantee the operational performance of filling and your lasting satisfaction.